Measurement scheme for electric vehicle drive system.

I. Introduction

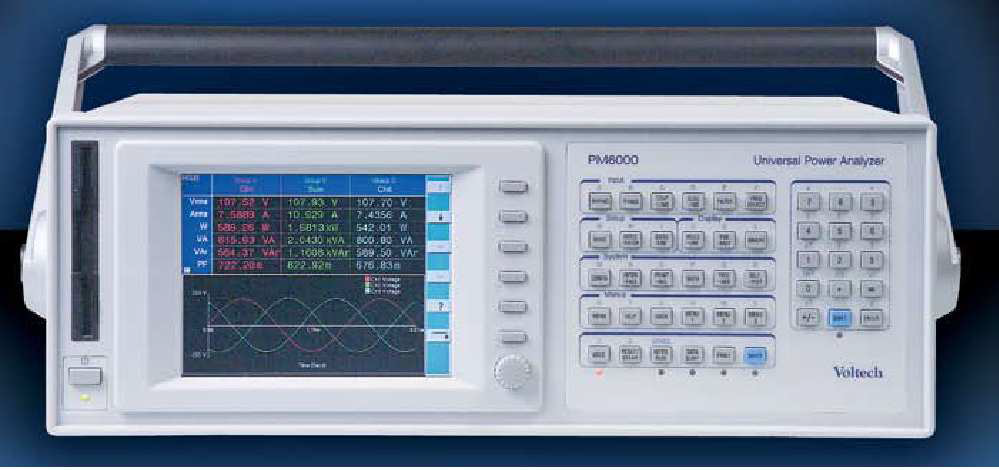

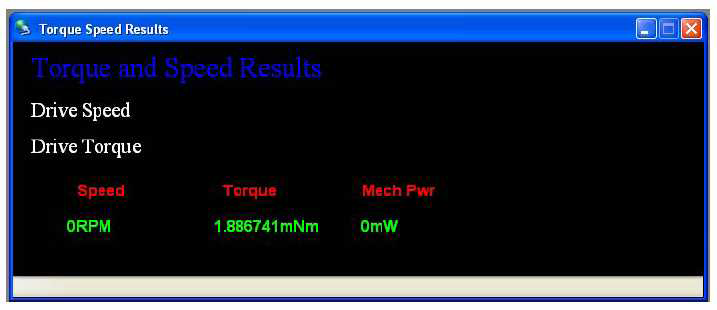

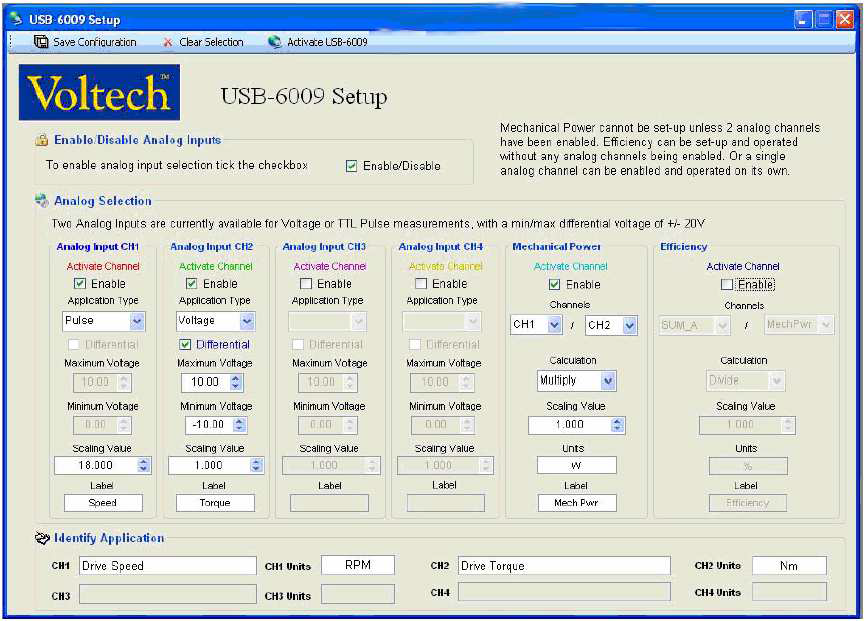

With the increasing attention to energy and environmental issues, electric vehicles are developing rapidly due to their advantages such as being clean and pollution-free, having high energy efficiency, low noise, and diverse energy sources. As a means of transportation, electric vehicles operate in a complex and changeable working environment. Their motor drive systems need to meet performance requirements such as high reliability, high efficiency, good adjustment performance, and low cost. Therefore, the testing of electric vehicle motor drive systems is an important research content. The following scheme uses the British Voltech PM6000 high-precision power analyzer as the main measurement equipment to provide a detailed description of the electric vehicle motor drive system. As shown in Figure 1, the quantities to be tested for the motor drive system are: four channels of current and four channels of voltage of the motor controller, including the input DC bus voltage and current and the output three-phase AC voltage and current values; the output torque and speed of the motor.

Small excavators are suitable for a variety of working environments, rather than manual working environments. Main users, ditches, landscaping, cable lines, trees planted on top of mountains, greenhouses for vegetables, improved agricultural land, basements, concrete, are other small Spaces. The machine adopts domestic engine, mechanical operation, ergonomic optimization, and unique joystick optimization to make the driver's operation more convenient and comfortable.

Small excavators can be used to dig greenhouses and ditches. This is a small excavator that can be used indoors. Saving labor and space is a rare advantage. It is widely used in the water business. Low cost purchase and high survival rate is everyone's evaluation. Not surprisingly, microshovels are also being used to build power projects. Filling the rod was previously a difficult task, as one had to use manual drilling and it was inefficient. Now everyone is using small excavators, nearly ten times faster than before. The other is called a multi-purpose mini excavator: not only does it have a bucket, it can also damage the ground and be equipped with a crushing hammer to tear down the house. Adding an auger can be a great aid in gardening tree holes and planting. Compared with ordinary excavators, micro drilling machines are small in size, easy to operate, and choose the built environment that many people like. Today, Xiaobian introduces how micro-drilling machines can help orchard construction in order to better understand micro-drilling machines.

Micro excavators dig ditches

It is mainly applicable to the loose land of agricultural vegetable greenhouses, the construction operations with narrow space such as the greening of municipal departments, planting trees and digging of orchard nurseries, breaking of concrete pavement, and mixing of sand and stone materials. It is the ideal equipment for continuously replacing labor and liberating labor force in the future.

Small excavators can be used to dig greenhouses and ditches. This is a small excavator that can be used indoors. Saving labor and space is a rare advantage. It is widely used in the water business. Low cost purchase and high survival rate is everyone's evaluation. Not surprisingly, microshovels are also being used to build power projects. Filling the rod was previously a difficult task, as one had to use manual drilling and it was inefficient. Now everyone is using small excavators, nearly ten times faster than before. The other is called a multi-purpose mini excavator: not only does it have a bucket, it can also damage the ground and be equipped with a crushing hammer to tear down the house. Adding an auger can be a great aid in gardening tree holes and planting. Compared with ordinary excavators, micro drilling machines are small in size, easy to operate, and choose the built environment that many people like. Today, Xiaobian introduces how micro-drilling machines can help orchard construction in order to better understand micro-drilling machines.

Small excavator is also known as small mining machinery, the definition of small excavator is also different, such as: in the country where the excavator loader is sold (such as the United Kingdom, France and Italy), 1 to 3 tons of small excavator products are the mainstream. In countries where the use of excavator loaders is not very common (such as Germany), it is more inclined to use 4-6 tons of products. However, almost all countries tend to buy larger equipment, so we conclude that the definition of small excavators is 1 to 6 tons of excavators can be called small excavators, of which 2.7 to 3.0 tons of products accounted for a larger proportion, the reason is that they can easily use common transport vehicles for ground transfer. Small excavators benefit from their small size and become ideal equipment for earthmoving applications mainly in urban areas.

A small excavator developed and manufactured for domestic modern and scientific production, suitable for all kinds of working environments instead of human labor, the main user orchard digging trenches, landscaping, cable pipelines, mountain planting trees, greenhouse vegetables, farmland transformation, basement, concrete crushing and other small Spaces. The equipment adopts domestic engine, mechanical control, ergonomic optimization and patented control handle, so that the driver's operation is more convenient and comfortable.

We’re just a few weeks away from SEMA 2017, and Mike and Jim Ring of Ringbrothers are burning the candle at both ends and in the middle to get three cars done for the show. They took time out of their busy schedule to talk to us on the podcast, though.

These sibling started out as two regular guys running their dad’s repair shop, and amazing as it may sound, they still churn out production collision work to keep the lights burning. But for a good chunk of the year, they’re banging out some of the coolest cars you’ve ever laid eyes on.

Witness 2014’s “Recoil,” the killer ’66 Chevelle that lit up social media after it was introduced in the Royal Purple booth that year.

Under the hood, the ’66 Chevelle features a Wegner Motorsports LS7 V-8, breathed on by a Whipple supercharger for 980 horsepower. One-off fuel rail covers exactly match the design of the blower’s case. The fuel injection system comes from Holley, with an Aeromotive fuel cell and pump.

The brothers are hard at work on three vehicles for the show this year, and as we talked, they emailed their renderings.

The first is an AMC Javelin AMX. We’ve seen some pretty wild two-seat AMX customs before, but it’s about time the four-seat Javelin AMX got its due. We’re dying to see what this one looks like when it’s finished.

The second is SEMA fodder: a 1969 Dodge Charger. But once Ringbrothers have their way with it, it’ll be stretched, widened, lowered and stuffed with the latest 1,000-hp mill from the SEMA floor.